Asset Tracking

Instant and

100% accurate

Track and manage your assets throughout their entire lifecycle with automated, real-time tracking using our RFID-powered solution.

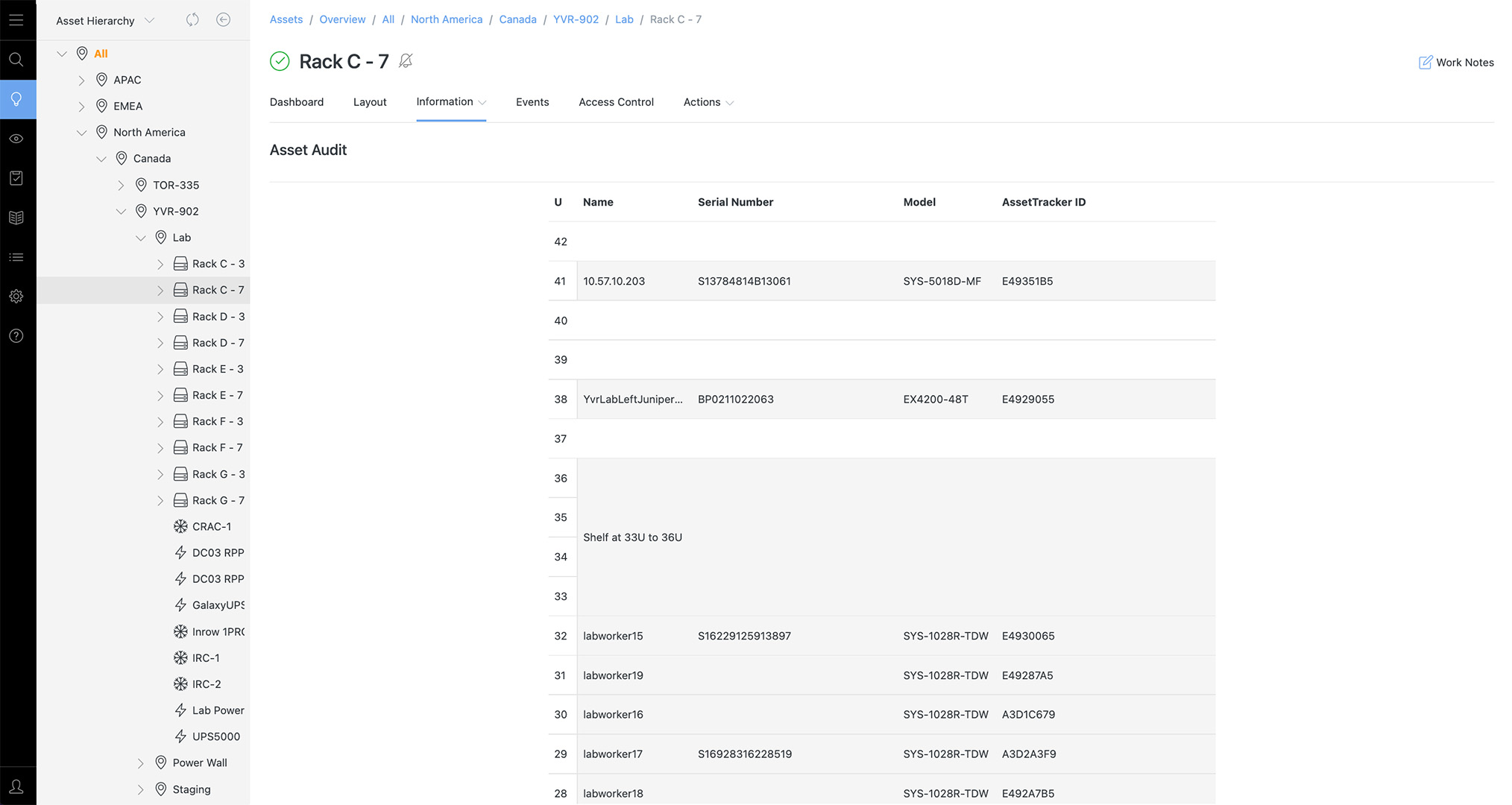

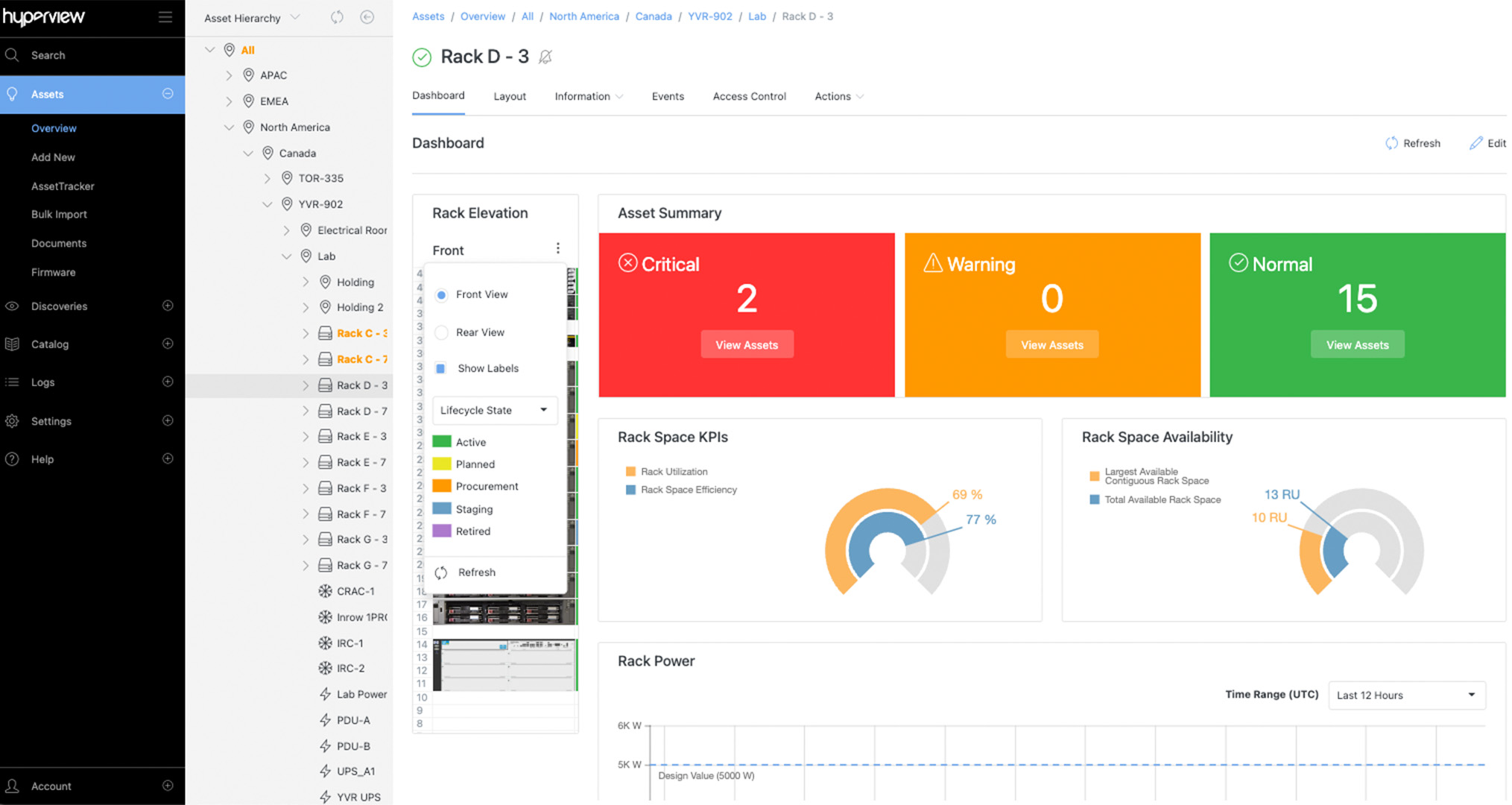

Know the rack-unit location of every asset

Track assets effortlessly with RFID tags. Location data is sent to Hyperview for continuous monitoring.

Eliminate manual data entry and physical audits

Produce precise audit reports for regulatory compliance. Hyperview tracks assets at every stage.

Protect against unauthorized asset moves or theft

Get alerts when an asset is relocated or removed from a rack-unit, or if an unknown asset is detected.

Asset Tracking

Instant and 100% accurate

Track and manage your assets throughout their entire lifecycle with automated, real-time tracking using our RFID-powered solution.

Know the rack-unit location of every asset

Track assets effortlessly with RFID tags. Location data is sent to Hyperview for continuous monitoring.

Eliminate manual data entry and physical audits

Produce precise audit reports for regulatory compliance. Hyperview tracks assets at every stage.

Protect against unauthorized asset moves or theft

Get alerts when an asset is relocated or removed from a rack-unit, or if an unknown asset is detected.

Replace error-prone manual processes with automated asset tracking

Replace error-prone manual processes with automated asset tracking

How does it work?

Our asset tracking solution seamlessly integrates with the platform and includes all necessary components – RFID asset tags, modules, gateways, and hubs – to effectively cover your assets.

After setting up the hardware, attach an asset tag to the asset using the 3M™ adhesive end and scan the QR code with an RFID reader. The unique tracking code will automatically appear in Hyperview for easy lifecycle management and audits.

When ready to place the asset in the rack, connect the magnetic end of its asset tag to the corresponding location on the module. Hyperview will instantly capture the asset’s location and match it with its tracking code, ensuring continuous monitoring for changes like relocation or removal.

How does it work?

Hyperview’s asset tracking solution fully integrates with the platform and comes with the necessary number of RFID asset tags, modules, gateways, and hubs to properly cover your asset estate.

Once the hardware has been installed and configured, the first step is to take an asset tag and apply the 3M™ adhesive end to the asset. Next, scan the QR code with an RFID reader. The asset’s unique tracking code is populated to the Hyperview platform, readying it for lifecycle management and audits.

After placing the asset in the rack, simply connect the magnetic end of its asset tag to the corresponding rack-unit location on the module. The asset’s location is immediately captured and matched to its tracking code in the platform and is now being monitored for any changes, such as a move or removal from its current placement.

Wait, there’s more…

Hyperview is an all-inclusive DCIM platform with awesome features to help you cut costs and manage risks like a pro. Explore the powerful tools included to level up your experience.

Wait, there’s more…

Hyperview is a feature-rich DCIM platform that gives you everything you need to save costs and mitigate risks. Explore some of the other powerful tools included in the product.